Our environmental impact

We understand that the process of designing and manufacturing efficiently in a world of scarce resources is an ongoing learning process and embrace that as a positive challenge.

These are some of the things that we do to move forward with our environment in mind:

The Dantech product range is designed and manufactured locally in Essex, about one hour away from central London. We are located efficiently to supply our UK and European customers from close by, allowing closer contact as well as reduced shipping requirements and lead times.

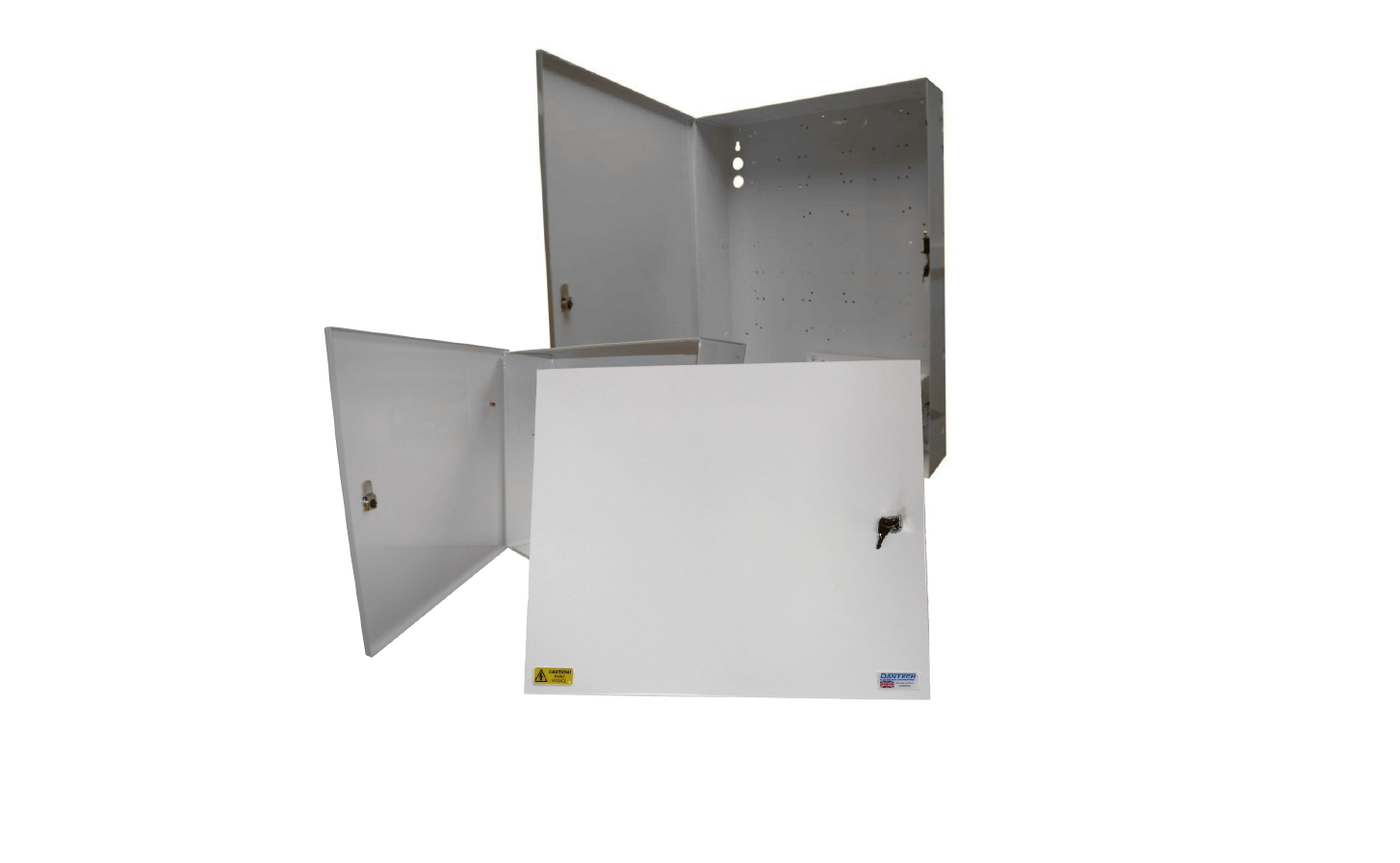

We design circuit layouts here, populate printed circuit boards with components, manufacture our metal plates, brackets and housings and build and test products before shipping to customers. This allows us to control the entire design process for products and packaging, specifying materials that are wherever possible recyclable and are not sourced from conflict areas.

We specify high energy efficiency and long-life components wherever possible to minimise the unnecessary power consumption of equipment whilst in service and wasteful product replacement activities.

Instead of shipping in bulky finished products from overseas, we purchase smaller component parts from our supply chain, reducing our carbon footprint.

We test all of our power supply, RTE switch and other electronic security products before shipping to our customers. This reduces the likelihood of unfortunate out of box failures and the need to ship returns and replacements.

Meanwhile, we are developing secure renewable power options for security, lighting and communications equipment. For example, we have off-grid eco CCTV power solutions for short term deployment through to 365-day autonomy.

Our production operation uses almost 100% low energy systems for machinery, heating and lighting, including the use of highly efficient AC servo metal punching, heat pump and LED technologies.

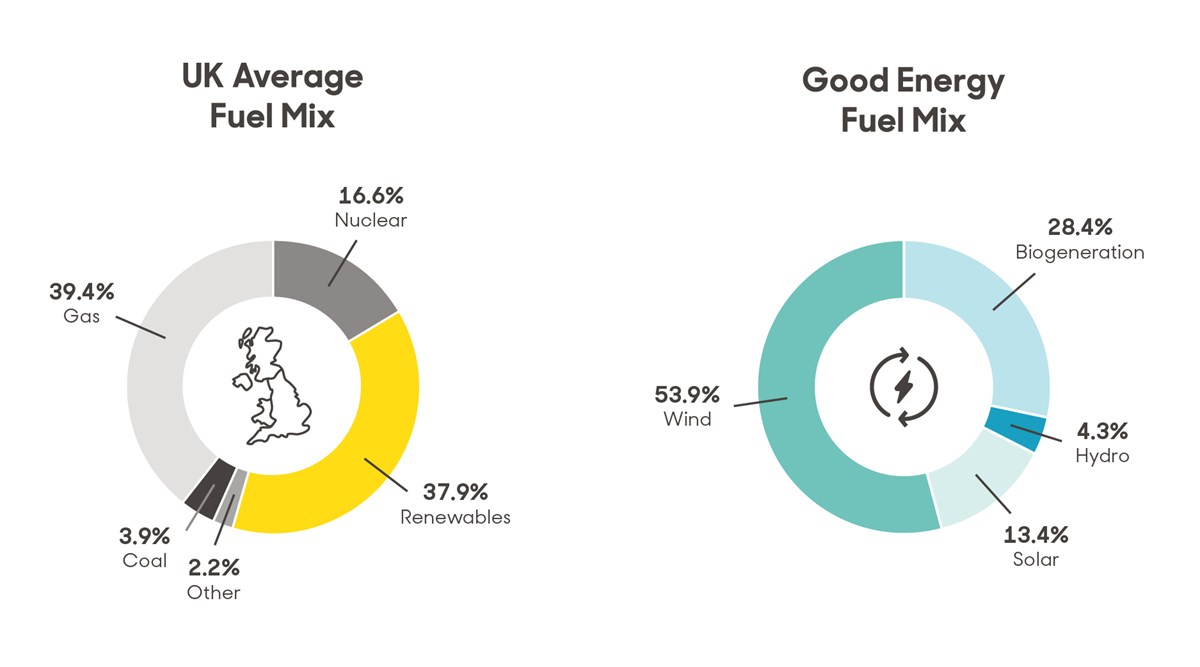

We are a 100% Eco electricity-powered company, through a mixture of responsible supply sourcing and eco self-generation.

Eco product design

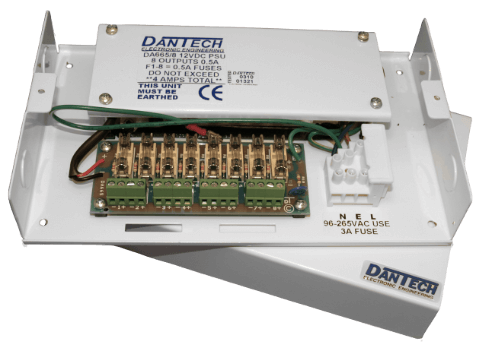

Around 90% of Dantech power product sales are of designs that have very high-efficiency levels, expected to be 85% - 95% output efficiency on load.

Our AC output products are highly efficient, typically providing over 90% efficiency at working load.

Our DC output products mostly use highly efficient switch-mode technology, providing a working efficiency of approximately 90%.

We have been designing and manufacturing higher efficiency switch mode power supply designs for over 25 years. In recent years advances in component design, reliability and availability have helped us to use high-efficiency technology in all-new designs. We are gradually converting the last of the traditional linear power supply designs to switch mode.

To help customers we will mark products with an ‘eco-friendly high-efficiency design’ badge.

We hope to achieve a 100% high-efficiency power product range in 2020.

.png)

.png)